History

Taiho (“TIE-ho“) Guitars, LLC is a one-man shop, based out of Macomb and Alcona Counties in Michigan (not affiliated with any multinational corporations or any other entity that use the “Taiho” name; see below).

I’ve been playing music for the majority of my life, and picked up the guitar in the late ’80s. Music has been a hobby and escape, but not the defining force. I’ve jammed in some bands and projects over the years, but the allure of a steady career and secure family life took precedence, so the rock-star lifestyle wasn’t for me.

My first commission came as a result of a casual conversation with my coworker. We usually start our day just chatting casually about the weekend or the night previous before diving into our work. When I mentioned that I’d finished up my third guitar build, she suddenly lit up and asked if I could build one for her husband.

When I posted photos of that project as well as a short video of me testing it out before delivery, I got another request from a friend. Now it seemed like it was getting a little more serious!

The Origin of “Taiho”

“Taiho” is derived from an alternate pronunciation of the Japanese characters of my last name. The logo is the kamon of my family.

I drew a following among my friends as I posted progress photos of each project. I originally posted my builds as a side category to my professional technology-oriented blog, Metalhead Tech. Interest in my work has been growing and that I realized I was blogging and cataloging more about guitar building than technology projects over at MHT. Taiho Guitars was spun off into its own entity.

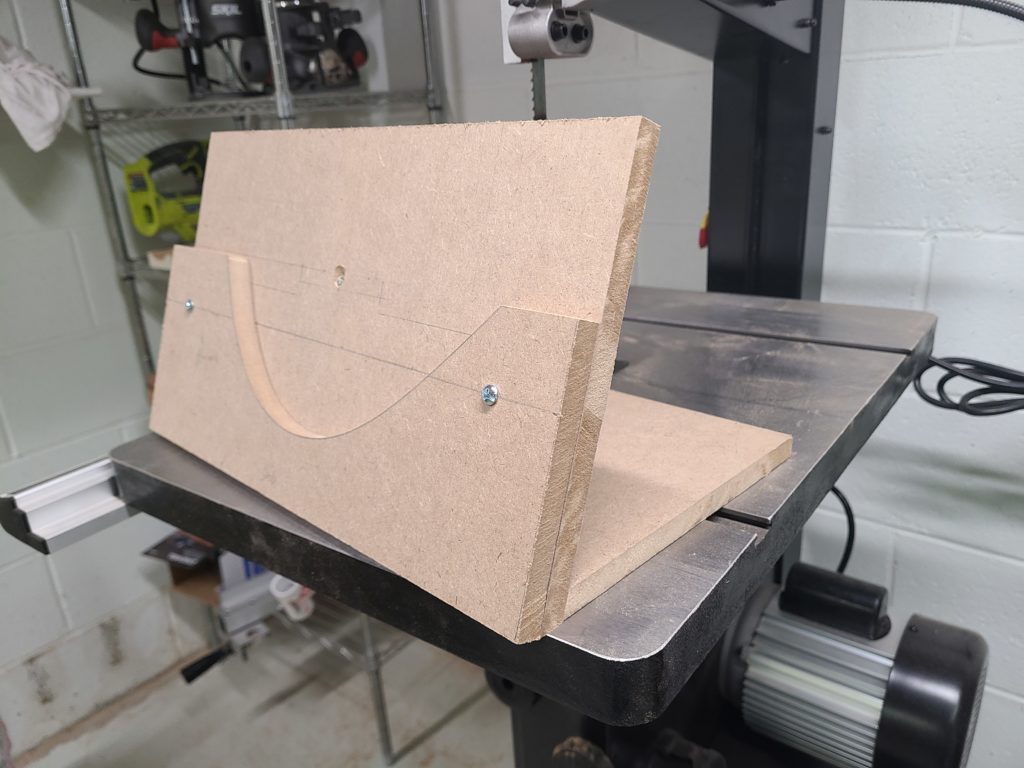

What started as a folding table, some hand tools, and improvising with hand-held power tools in our country vacation home is expanding into a growing workshop. Builds began with import kits and Warmoth components. Bodies are now being cut from blanks, starting with Chevelle and Nazgûl.

The workshop now features a drill press, oscillating belt/spindle sander, band saw, and an air compressor that drives a spray gun, along with two workbenches I built using 2×4s and plywood.